Amathuluzi esimanje okusika ahlangabezane neminyaka engaphezu kweyi-100 yomlando wokuthuthuka kusukela kunsimbi yensimbi ye-carbon kuya ensimbi yamathuluzi enesivinini esikhulu,i-carbide enosimende, ithuluzi le-ceramicfuthisuperhard ithuluzi materials. Engxenyeni yesibili yekhulu le-18, ithuluzi lokuqala laliyinsimbi yensimbi ye-carbon. Ngoba ngaleso sikhathi yayisetshenziswa njengento enzima kakhulu eyayingashintshwa ibe amathuluzi okusika. Kodwa-ke, ngenxa yezinga lokushisa eliphansi kakhulu elimelana nokushisa (ngaphansi kuka-200 ° C), izinsimbi ze-carbon thuluzi zinezinkinga zokuba ngokushesha futhi zibe buthuntu ngenxa yokusika ukushisa lapho zisika ngesivinini esikhulu, futhi ububanzi bokusika bulinganiselwe. Ngakho-ke, sibheke ngabomvu izinto zamathuluzi ezingasikwa ngesivinini esikhulu. Izinto ezivelayo ezibonisa lokhu okulindelekile yinsimbi enesivinini esikhulu.

Insimbi enesivinini esikhulu, eyaziwa nangokuthi insimbi yangaphambili, yathuthukiswa ososayensi baseMelika ngo-1898. Ayiningi kakhulu ukuthi iqukethe ikhabhoni encane kunensimbi yensimbi ye-carbon, kodwa leyo tungsten yengezwa. Ngenxa yendima ye-tungsten carbide eqinile, ubulukhuni bayo abuncishisiwe ngaphansi kwezimo zokushisa eziphakeme, futhi ngenxa yokuthi inganqunywa ngesivinini esiphezulu kakhulu kunejubane lokusika lensimbi yensimbi ye-carbon, ibizwa ngokuthi insimbi yesivinini esikhulu. Kusukela ngo-1900 ~ -1920, insimbi enesivinini esikhulu ene-vanadium ne-cobalt yavela, futhi ukumelana nokushisa kwayo kwanda kwafika ku-500 ~ 600 ° C. Ijubane lokusika lensimbi yokusika lifinyelela ku-30 ~ 40m / min, elikhuphuka cishe izikhathi ezingu-6. Kusukela lapho, ngokwenziwa kwe-serialization yezakhi zayo, i-tungsten ne-molybdenum steels ezinesivinini esikhulu zenziwe. Isasetshenziswa kabanzi kuze kube manje. Ukuvela kwensimbi enesivinini esikhulu kubangele a

inguquko ekusetshenzisweni kokusika, ukuthuthukisa kakhulu ukukhiqiza kokusika kwensimbi, futhi kudinga ukuguqulwa okuphelele kwesakhiwo sethuluzi lomshini ukuze livumelane nezidingo zokusebenza zokusika zaleli thuluzi elisha. Ukuvela nokuthuthukiswa okuqhubekayo kwamathuluzi emishini emisha, nakho, kuye kwaholela ekwakhiweni kwezinto ezingcono zamathuluzi, futhi amathuluzi avuselelwe futhi athuthukiswa. Ngaphansi kwezimo ezintsha zobuchwepheshe bokukhiqiza, amathuluzi ensimbi anesivinini esiphezulu nawo anenkinga yokukhawulela ukuqina kwethuluzi ngenxa yokusika ukushisa lapho usika ngesivinini esikhulu. Lapho isivinini sokusika sifinyelela ku-700 ° C, insimbi enesivinini esikhulu

ithiphu ibuthuntu ngokuphelele, futhi ngesivinini sokusika ngaphezu kwaleli xabiso, akunakwenzeka ngokuphelele ukusika. Ngenxa yalokho, izinto zamathuluzi e-carbide ezigcina ubulukhuni obanele ngaphansi kwezimo zokushisa eziphakeme zokusika kunalezi ezingenhla ziye zavela futhi zingasikwa emazingeni okushisa aphezulu okusika.

Izinto ezithambile zingasikwa ngezinto eziqinile, futhi ukuze usike izinto eziqinile, kuyadingeka ukusebenzisa izinto ezinzima kunazo. Into enzima kakhulu eMhlabeni okwamanje idayimane. Nakuba sekuyisikhathi eside amadayimane emvelo atholakala emvelweni, futhi anomlando omude wokuwasebenzisa njengamathuluzi okusika, amadayimane okwenziwa nawo aye ahlanganiswa ngempumelelo ekuqaleni kwawo-50s wekhulu lama-20, kodwa ukusetshenziswa kwangempela kwedayimane ukwenza kabanzi.izimboni cutting ithuluzi materialskuseyindaba yamashumi eminyaka amuva nje.

Ngakolunye uhlangothi, ngokuthuthukiswa kobuchwepheshe besimanje bomkhathi kanye nobuchwepheshe be-aerospace, ukusetshenziswa kwezinto zobunjiniyela besimanje kuya kuyanda kakhulu, nakuba insimbi enesivinini esiphezulu ethuthukisiwe, i-carbide enosimende, kanyeizinto ezintsha ze-ceramic zamathuluziekusikeni kwezinto zokusebenza zokucubungula zendabuko, isivinini sokusika kanye nokusika umkhiqizo kuphindwe kabili noma izikhathi eziningi zanda, kodwa lapho uzisebenzisa ukucubungula izinto ezingenhla, ukuqina kwethuluzi nokusebenza kahle kokusika kusephansi kakhulu, futhi ikhwalithi yokusika kunzima ukuyiqinisekisa, ngezinye izikhathi ngisho ayikwazi ukucubungula, isidingo sokusebenzisa izinto zamathuluzi ezibukhali nezingagugi.

Ngakolunye uhlangothi, ngokuthuthuka okusheshayo kwesimanjeukukhiqiza imishinikanye nomkhakha wokucubungula, ukusetshenziswa okubanzi kwamathuluzi omshini ozenzakalelayo, izikhungo zemishini yokulawula izinombolo zekhompyutha (CNC), kanye nemihlangano yokucobelelana ngolwazi yomshini engenamuntu, ukuze kuthuthukiswe ukunemba kokucubungula, ukunciphisa isikhathi sokushintsha amathuluzi, nokuthuthukisa ukusebenza kahle kokucubungula, izidingo ezengeziwe eziphuthumayo zenziwa ukuze kube nezinto zamathuluzi ezihlala isikhathi eside nezizinzile. Kulokhu, amathuluzi edayimane athuthuke ngokushesha, futhi ngesikhathi esifanayo, ukuthuthukiswa kwediamond ithuluzi materialsnayo ikhuthazwe kakhulu.

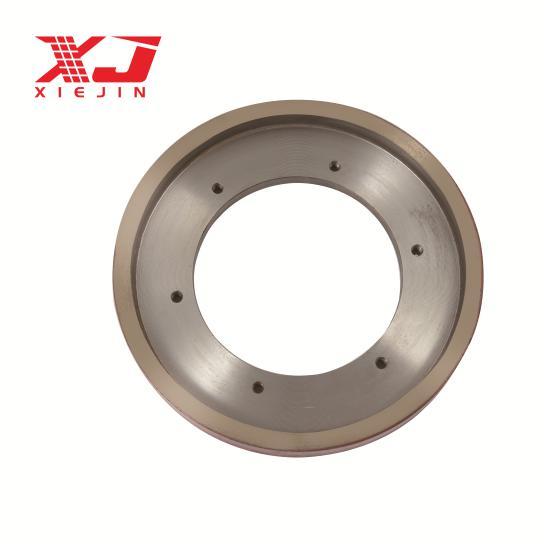

Izinto zethuluzi ledayimaneube nochungechunge lwezakhiwo ezinhle kakhulu, ezinokunemba okuphezulu kokucubungula, isivinini sokusika okusheshayo kanye nempilo ende yesevisi. Isibonelo, ukusetshenziswa kwamathuluzi e-Compax (i-polycrystalline diamond composite sheet) kungaqinisekisa ukucutshungulwa kwamashumi ezinkulungwane zezingxenye zendandatho ye-silicon aluminium alloy piston kanye namathiphu abo amathuluzi ngokuyisisekelo awashintshile; Imishini yokusika i-aluminium yendiza enezisiki zokugaya ezinobubanzi obukhulu be-Compax ingafinyelela isivinini sokusika esingafika ku-3660m/min; Lezi azinakuqhathaniswa namathuluzi e-carbide.

Akukhona lokho kuphela, ukusetshenziswadiamond ithuluzi materialsingaphinda yandise insimu yokucubungula futhi iguqule ubuchwepheshe bokucubungula bendabuko. Esikhathini esidlule, ukucutshungulwa kwesibuko bekungasebenzisa kuphela inqubo yokugaya nokupholisha, kodwa manje amathuluzi edayimane e-crystal eyodwa kuphela engokwemvelo, kodwa futhi kwezinye izimo angasetshenziswa futhi amathuluzi ahlanganisiwe we-PDC aqinile okusika okuseduze okunembe kakhulu, ukufeza ukujika esikhundleni sokugaya. Ngokusetshenziswa kweamathuluzi anzima kakhulu, eminye imiqondo emisha iye yavela emkhakheni wokwenza imishini, njengokusetshenziswa kwamathuluzi e-PDC, isivinini sokunciphisa umkhawulo akuselona ithuluzi kodwa ithuluzi lomshini, futhi lapho isivinini sokuphenduka sidlula isivinini esithile, i-workpiece kanye nethuluzi akushisi. Imithelela yale miqondo eyisisekelo ijulile futhi inikeza amathemba angenamkhawulo embonini yesimanje yokwenza imishini.

Isikhathi sokuthumela: Nov-02-2022